High quality surface finishing services improve aesthetics and functions of your parts regardless of the manufacturing process used. Choose from the suitable of surface treatment methods for your plastic and metal production parts.

ISO9001:2015 & IATF 16949: 2016 & ISO13485:2016 IEC27001:2013

TS Prototypes is committed to providing assured quality and service

We provides various finishing services for our customers to meet the surface requirements, These finishing techniques serve different purposes and can be applied to various materials to enhance their appearance, protect them from corrosion, or provide specific functional properties

Spray painting、Anodizing、Electroplating、Sand blasting、Silk screening、Polishing、Chromating、Bake finish、Laser etching、High glaze、UV-finish、Transfer-printing、Embossing、Cleaning、Fuming PC、Scouring/brushing

Spray painting is a method of applying paint or coating using pressurized air to create a fine mist of paint particles. It is a versatile and commonly used finishing technique for a wide range of materials and surfaces. Spray painting allows for a smooth and even application of paint, providing a uniform appearance and protective layer.

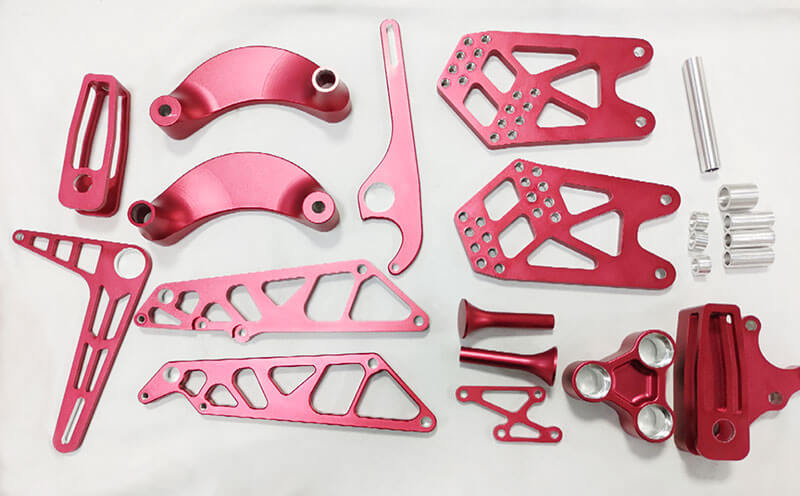

Anodizing is an electrochemical process that enhances the corrosion resistance and durability of metal surfaces, primarily aluminum. It involves creating an oxide layer on the surface of the metal by immersing it in an electrolytic solution and applying an electric current. Anodizing can also provide decorative options as the oxide layer can be dyed in various colors.

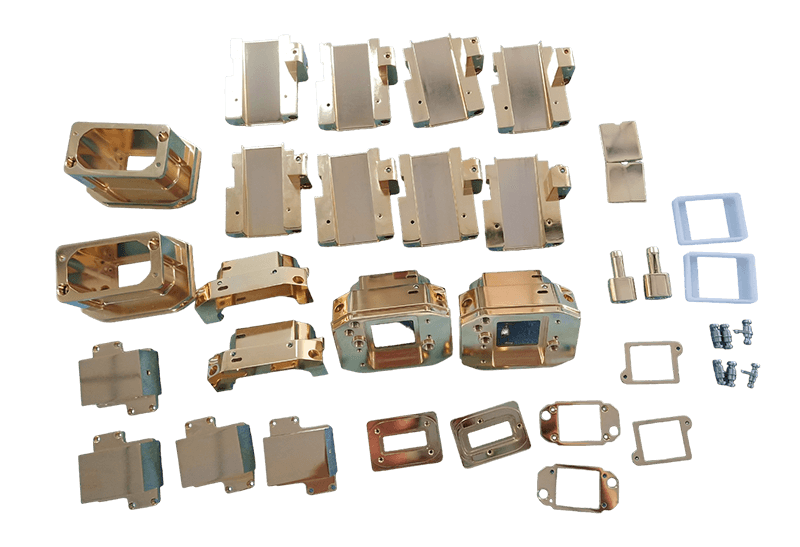

Electroplating is a process of depositing a metal coating onto a substrate through the use of an electric current. It involves immersing both the substrate and a metal electrode into an electrolyte solution and passing a direct electric current between them. The metal ions in the solution are attracted to the substrate and form a thin, protective layer of metal coating on its surface. Electroplating can enhance the appearance, corrosion resistance, and durability of the substrate.

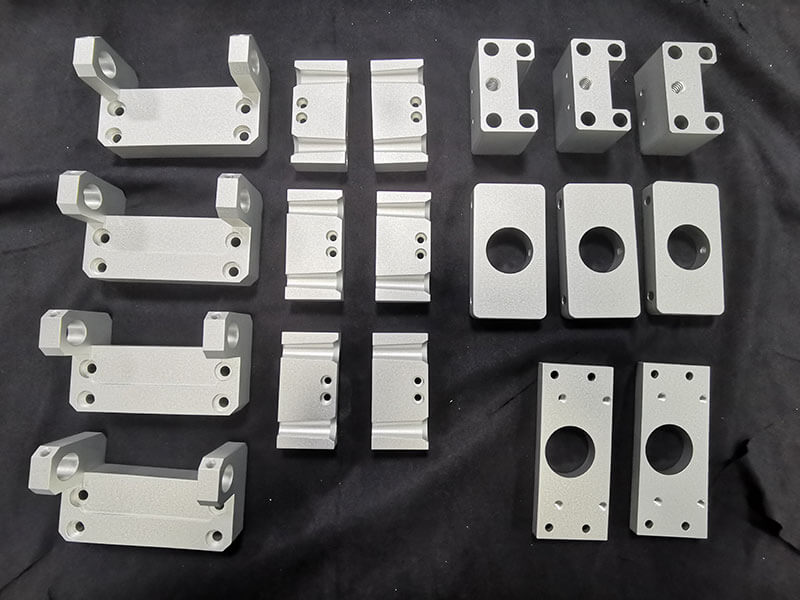

Sandblasting, also known as abrasive blasting, is a technique used to clean, smooth, or roughen the surface of a material by propelling fine particles or abrasives at high velocity. It involves using compressed air or a centrifugal wheel to propel the abrasive material, such as sand, onto the surface. Sandblasting is commonly used for surface preparation before painting or coating, as it removes rust, scale, paint, and other contaminants.

Silk screening, also called screen printing, is a method of printing images or designs on various materials, such as fabric, paper, plastics, and metals. It involves creating a stencil, known as a screen, by blocking off areas where the ink should not be applied. The screen is then placed over the material, and ink is forced through t

Polishing is a finishing process that involves smoothing and refining the surface of a material to improve its appearance, texture, and reflectivity. It is commonly done using abrasives, such as sandpaper or polishing compounds, along with mechanical or chemical means. Polishing can remove imperfections, scratches, and dullness from the surface, resulting in a smooth and shiny finish.