From prototypes to rapid tooling to large scale production. We provide kinds product development solutions to make your design into production and input to market.

ISO9001:2015 & IATF 16949: 2016 & ISO13485:2016 IEC27001:2013

TS Prototypes is committed to providing assured quality and service

Common materials: Common materials ensure quick possible delivery, including Aluminum, steel, brass, ABS, PMMA, PP, PC, etc.

Special materials: Source as per your requirements

Customer supplied materials: You can send your unique or preferred material to us to produce parts

Rapid prototype to large-scale production

Without MOQ, we provide various manufacturing ways for you. Rapid tooling/simple mold/silicone mold is available if you prefer a small batch of plastic/metal parts

Factories of our own can remove many obstacles of communication, cost control, and troubleshooting. TS Prototypes is an integrated OEM company that covers the main OEM manufacturing ways.

Precise CNC machines and EDM equipment

Tooling/mold services are complicated and precise. We have a complete workflow to guarantee your mold to be delivered to you timely.

Depending on your requirement, we are capable to provide you with surface finishing such as polishing, painting, burring, etc. with our manual department. Additionally, we work great and reliably with our suppliers for more finishing services.

We have the necessary certifications for your projects from quality to information security.

ISO 9001: Quality system

IATF 16949: Supplementary certification for automotive industries

ISO/ISC 27001: Information security system

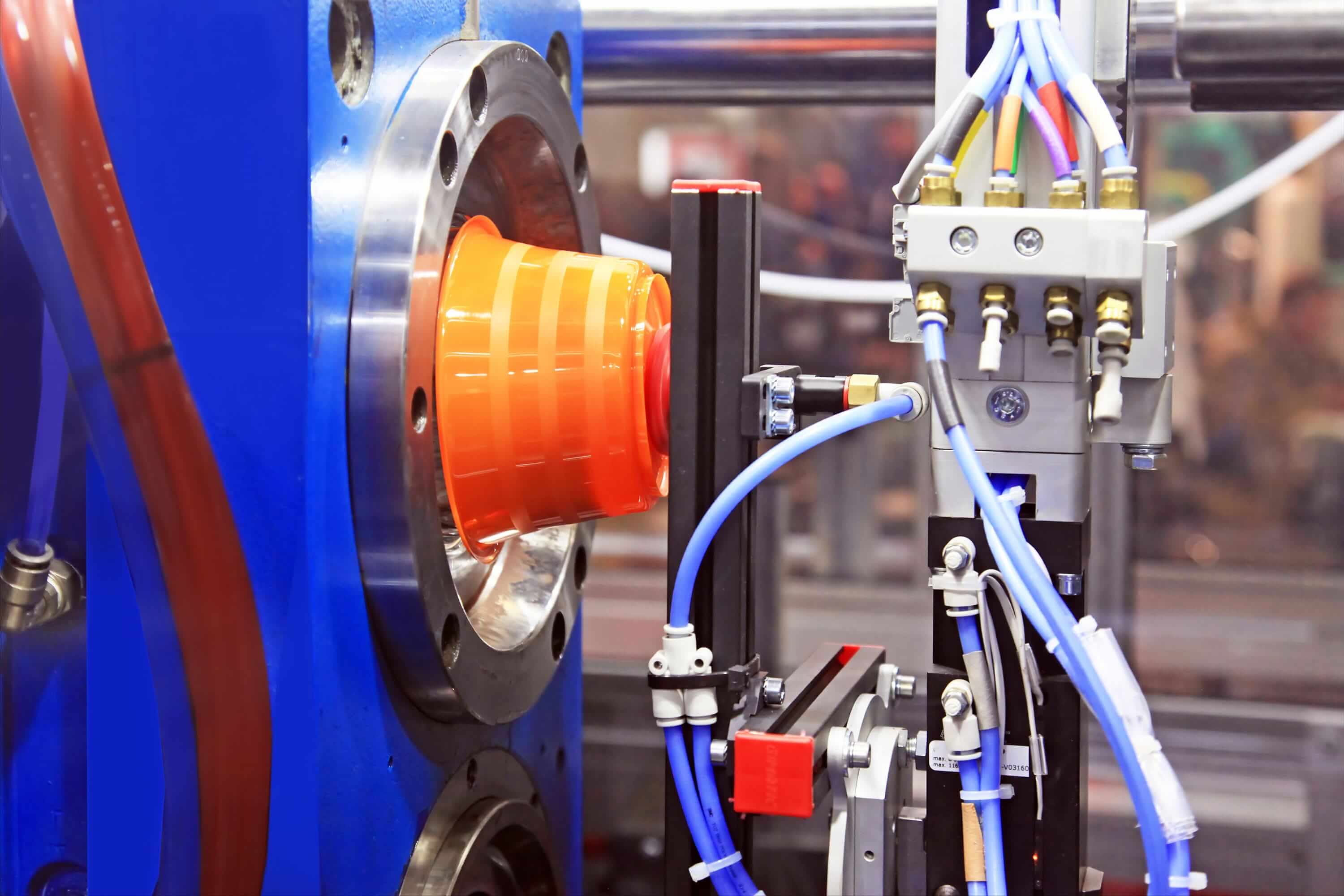

We have injection molding machines from 80T to 1600T that can produce common size injection molded parts. The tonnage calculation/clamping force is one of the key factors for quality and cost. It keeps the tooling closed during the injection process. The higher tonnage, the higher weight of tooling it can keep.

CNC Tooling

We have domestic and imported tooling from Switzerland and Japan.

Precision: ±0.005mm

RPM: 2,400-20,000

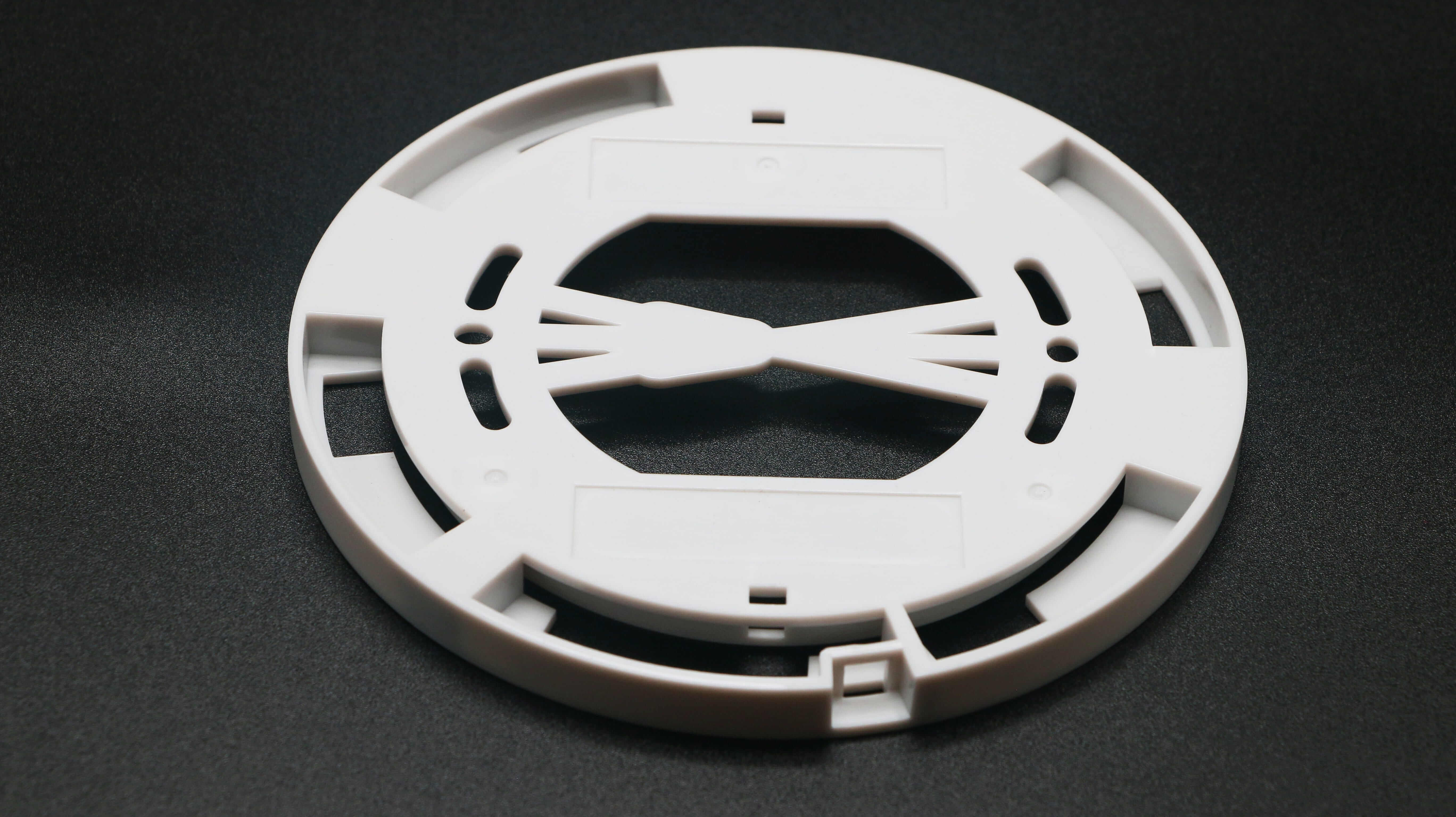

It is designed especially for the mass production of plastic parts by repeatedly using the same mold. You will find the consistency of color, size, structure, shape on the injection molded parts. Depending on your volume request and mold, hundreds of thousands of custom parts can be produced.

MIM(metal injection molding) uses metal powder and binder to be injected into the mold. MIM is an innovative technology that achieve the combination of small metal part and large-scale production. It is suitable for custom, small, complex metal parts.

Add plastic materials(pellets) into the hoppe

Pellets will be heated and melted down in the barrel

The heated plastic is injected into the mold through the nozzle

Plastic is allowed to cool and harden in the mold

The mold opens and ejects the parts

Automotive、Home appliance、Medical、Aerospace、Robotics、Consumer、Electronics、Defense、Engineering