CNC Machining: CNC (Computer Numerical Control) machining is a process of using computer-controlled machinery to precisely cut and shape materials. In home appliance manufacturing, CNC machining is commonly used to produce metal casings, panels, frames, and internal components.

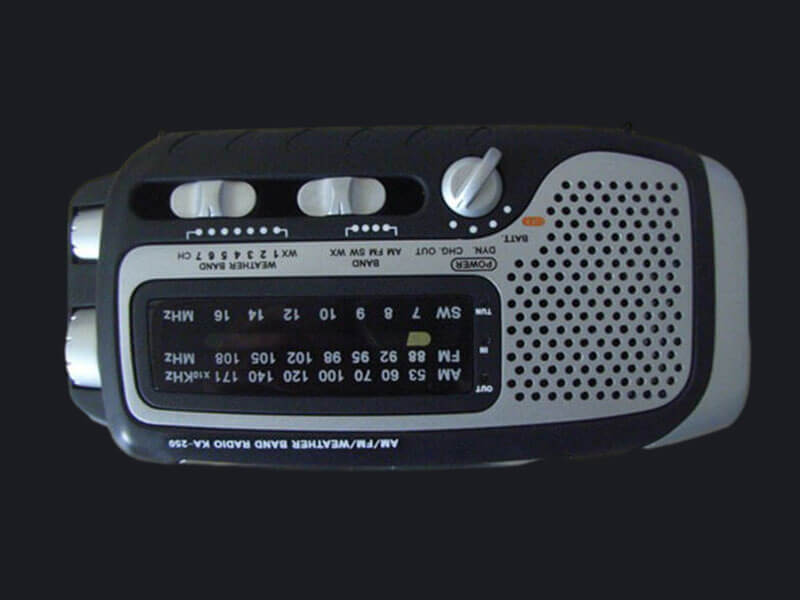

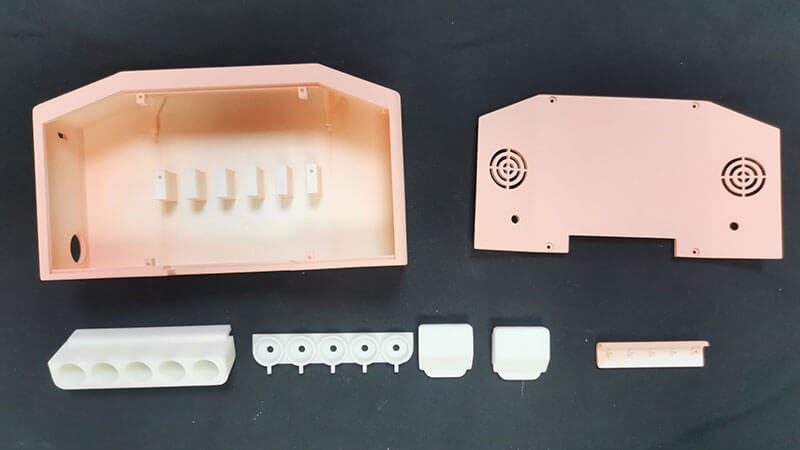

Plastic Injection Molding: Injection molding involves injecting molten plastic material into molds, which are then cooled and solidified to form the desired parts and components. In home appliance manufacturing, injection molding is commonly used to produce plastic casings, buttons, connectors, and accessories.

Sheet Metal Fabrication: Sheet metal fabrication involves cutting, bending, punching, and welding metal materials to create the desired shapes and structures. In home appliance manufacturing, sheet metal fabrication is commonly used to produce machine housings, frames, casings, and internal components.

Die Casting: Die casting involve injecting molten metal into molds, which are shaped and structured through high pressure or gravity. In home appliance manufacturing, die casting and casting are commonly used to produce metal casings, heat sinks, internal frames, and connecting parts.

Plating and Coating: Plating and coating are common surface treatment methods in home appliance manufacturing. Plating can create a thin layer of coating on the metal surface to improve corrosion resistance and aesthetic quality. Coating, on the other hand, provides color and decorative effects to home appliance products.

These machining services play a significant role in home appliance manufacturing, ensuring product quality, functionality, and aesthetics. They provide customized and high-precision solutions to meet the requirements and specifications of different home appliance products.

TS Prototypes has 12 years of machining and manufacturing experience, providing customers with efficient and comprehensive processing services including CNC Machining, Plastic Injection Molding, Sheet Metal Fabrication, Die Casting process, as well as Plating and Coating surface finishing to meet customer requirements for various requirements for components