On-demand prototypes to production with low price and fast speed.

ISO9001:2015 & IATF 16949: 2016 & ISO13485:2016 IEC27001:2013

TS Prototypes is committed to providing assured quality and service

3D printing is a kind of additive manufacturing technologies, which includes SLA,SLM and SLS. they process 3D object by the continuous physical layer.

Providing the high-quality products in short days is our mission. 3D printing did it, even for the complicate structure parts. 3D printing is the future direction to produce the prototypes with low price and fast speed. TS have much experience in this line, and we can make the clear PC products via SLA with continuous innovation and testing.

Overall, Kingsheng's THT assembly service provides a reliable and cost-effective solution for customers who require through-hole

component assembly for their electronic products.

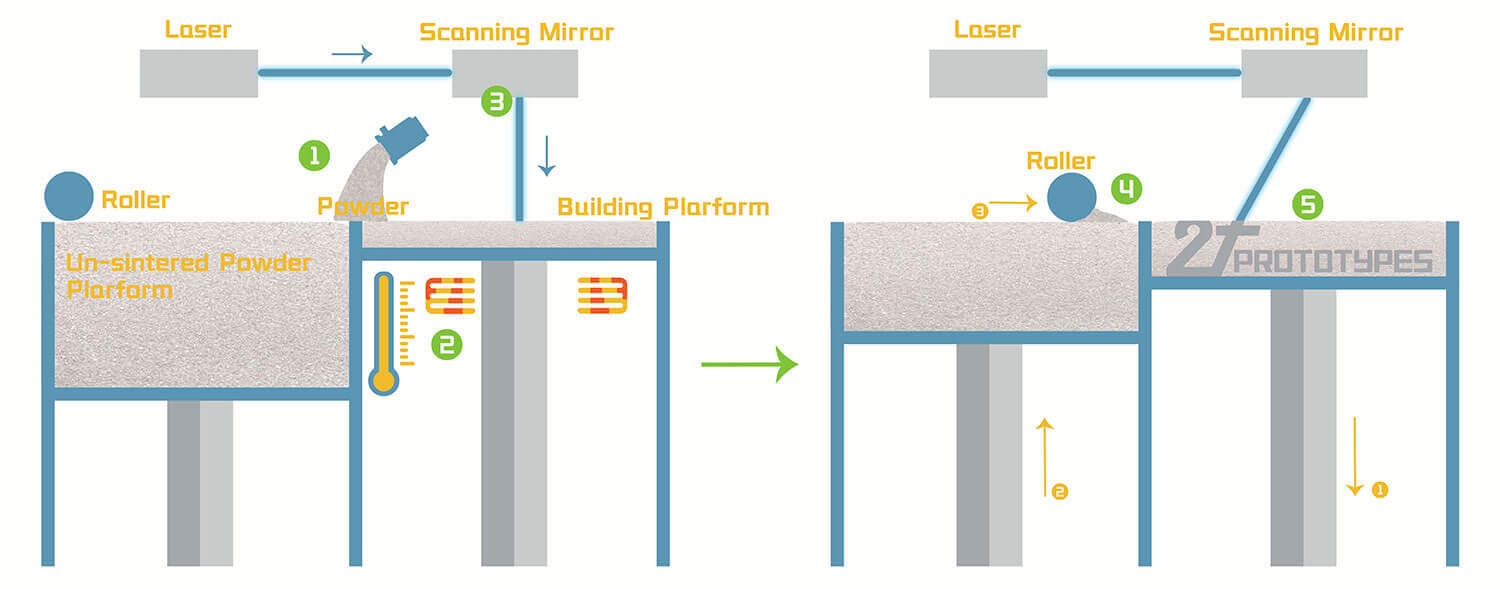

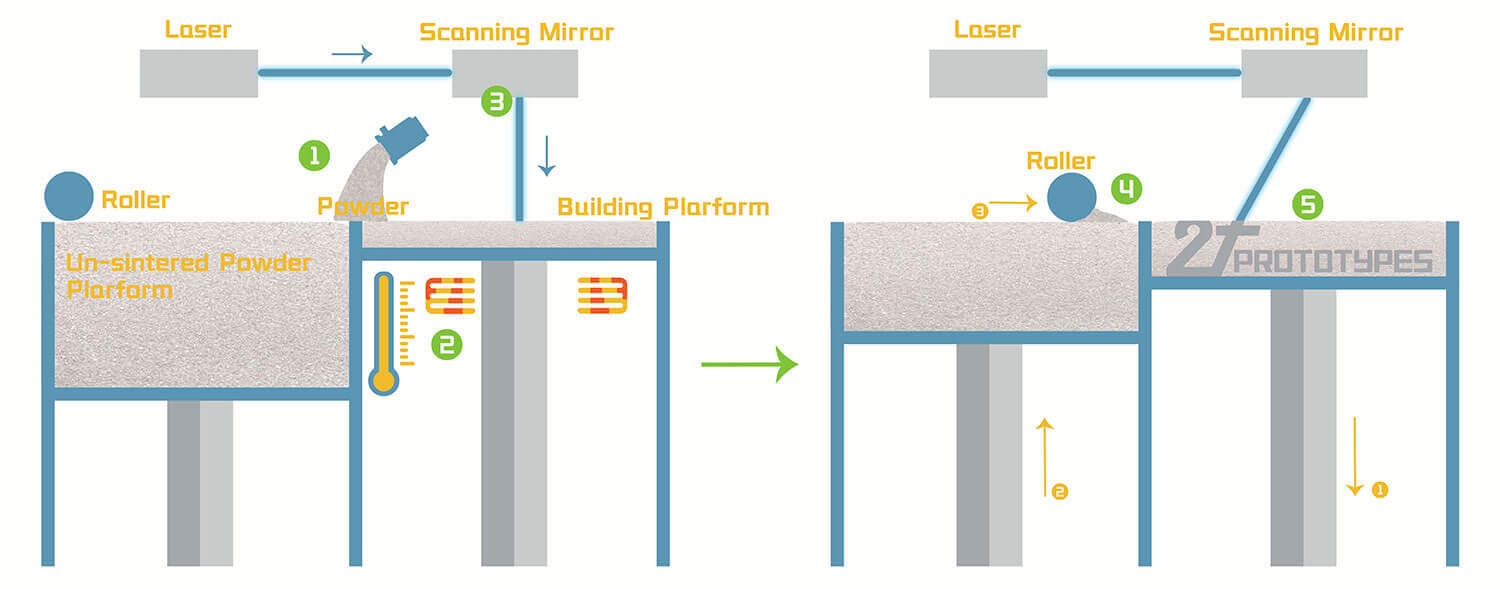

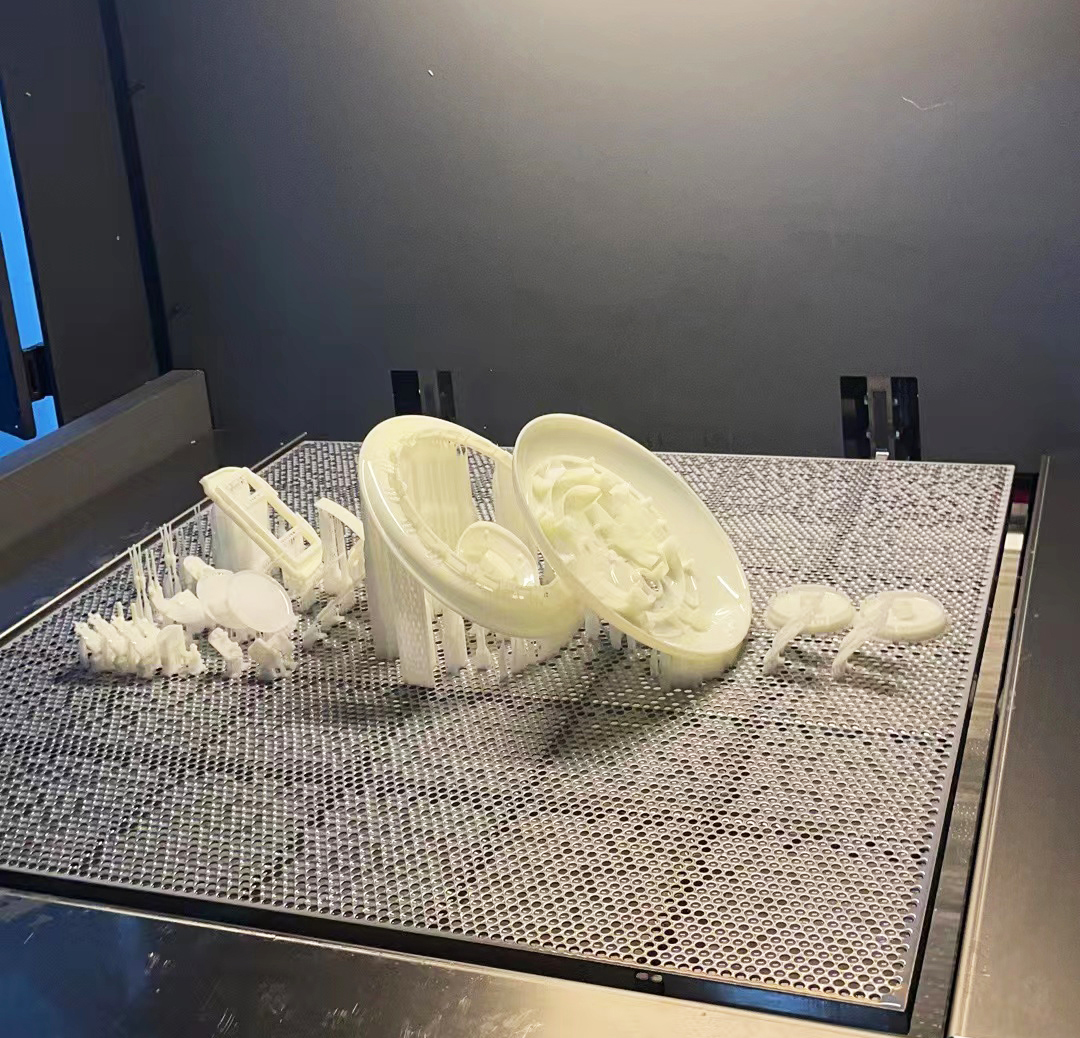

SLS (Selective Laser Sintering) printing fuse the powder (typically nylon powder) to form the part by laser technology. Without additional supporting materials, the SLS printed parts allow high flexibility and are very suitable for functional parts and moving parts from prototypes. Parts can be assembled or jointed.

SLA (Stereo lithography Appearance) printing is applicable to presentation prototypes, concept models, and translucent prototypes. To create parts, the process cures the photopolymer layer by layer by UV light. SLA technology becomes popular because of the result of high resolution.

We use SLM (Selective Laser Melting) to print metal parts. The metal powder will be melted and formed layer by layer to build the part. 3D printing manufacturing reduces material waste and enhances the flexibility of the design. That’s why metal printing to be a popular alternative to machining services.upgrading these devices.

SLA material: Clear PC, ABS-like, Semi-translucent resin

SLS material: PA, PA+GF

SLM material : Aluminum, Titanium, and Steel

1. Fast

2. Low price, economical

3. Complex structures

4. Widely used in industrial, automotive, medical, consumer electronics industries etc

SLS (Selective Laser Sintering) printing fuse the powder (typically nylon powder) to form the part by laser technology. Without additional supporting materials, the SLS printed parts allow high flexibility and are very suitable for functional parts and moving parts from prototypes. Parts can be assembled or jointed.

The powder to be spread in a thin and dense layer on top of a platform.temperature to make it easier for fusing.

The platform to be heated below the melting temperature to make it easier for fusing.

A laser selectively scans the powder and sinters them according to the cross-section contour of the layer.

A Powder spreader such as a blade or roller creates a thin and uniform layer for the next layer fusing.temperature to make it easier for fusing.

This process is repeated until all layers are sintered.

Remove and clean the loose powder to get the part after the printing process.

SLA (Stereo lithography Appearance) printing is applicable to presentation prototypes, concept models, and translucent prototypes. To create parts, the process cures the photopolymer layer by layer by UV light. SLA technology becomes popular because of the result of high resolution.

The UV laser beam scans the cross-section of the part by the reflection of the lens.temperature to make it easier for fusing.

The scanned liquid material is hardened to be a single layer.

The building platform is indexed down and the recoater blade slides to create a new layer.

This process is repeated until all layers are hardened.

Clean the additional resin and complete the final cure.

Overall, Kingsheng's THT assembly service provides a reliable and cost-effective solution for customers who require through-hole

component assembly for their electronic products.

The metal powder will be melted and formed layer by layer to build the part. 3D printing manufacturing reduces material waste and enhances the flexibility of the design. That’s why metal printing to be a popular alternative to machining services.

The metal powder will be melted and formed layer by layer to build the part. 3D printing manufacturing reduces material waste and enhances the flexibility of the design. That’s why metal printing to be a popular alternative to machining services.

The metal powder will be melted and formed layer by layer to build the part. 3D printing manufacturing reduces material waste and enhances the flexibility of the design. That’s why metal printing to be a popular alternative to machining services.