Prototypes to on demand production of sheet metal parts by laser cutting, bending, stamping processing.

ISO9001:2015 & IATF 16949: 2016 & ISO13485:2016 IEC27001:2013

TS Prototypes is committed to providing assured quality and service

Sheet metal is a kind of technology to bending or pressing as the 3D drawings. There are many standard thickness materials like Aluminum, steel, spring steel, copper etc. which are widely used in enclosures, brackets, casing, cabinets, housings parts. It’s also a fast and economical method for prototypes and low-volume production.

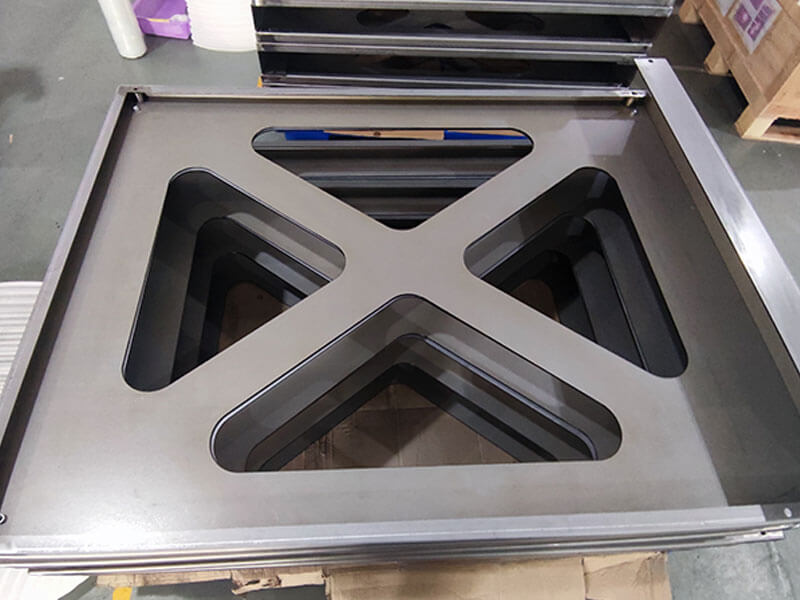

Sheet metal bending can form the parts by applying force to sheet metal. It is a fast and easy way for small-batch sheet metal parts without too many cutting requirements.

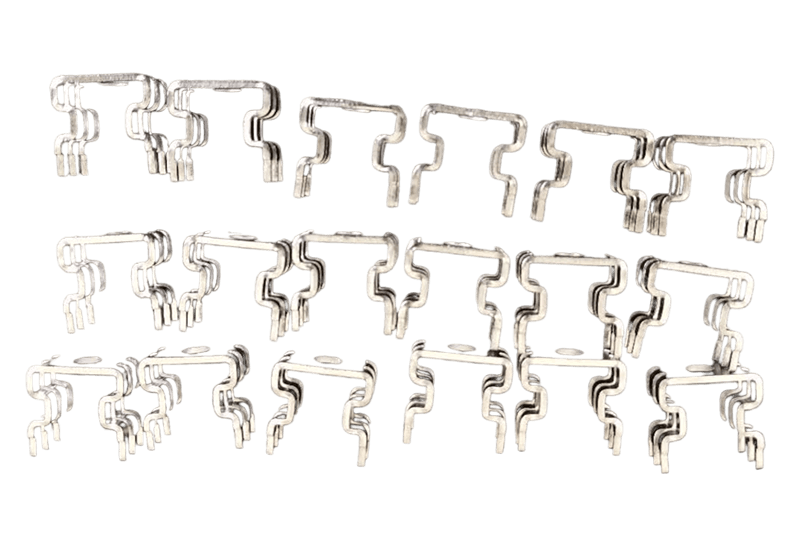

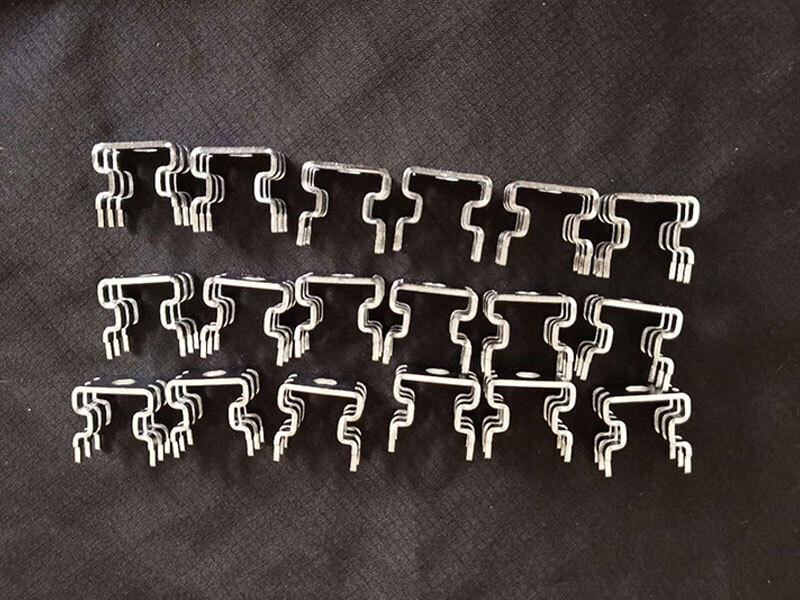

Stamping uses a press to force a die into the metal to create the requested part shape and size. It is usually used in the manufacturing of large-scale identical parts.

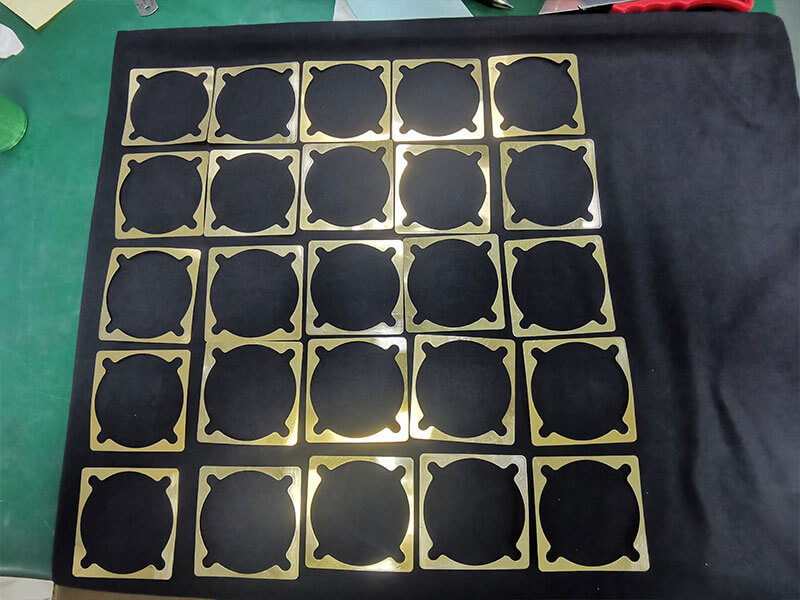

Laser cutting uses a high-power laser to cut the sheet metal material. The cutting edges are elaborately and precisely than other working ways.

Custom metal fabricated parts have to follow industry standards. We pass certificates of ISO 9001, IATF 16949, and information security. That means our metal fabrication service conforms to the International standard strictly. We operate multiple advanced machines to meet the need for sheet metal fabrication.

It is a time-consuming hassle to communicate with more than one supplier. Today’s industrial and manufacturing operations are more varied than ever. A metal fabricated company that can provide flexible and complete services is in greater need. Our diverse service combination can meet the special need of every project.

We are committed to eliminating unnecessary communication and perfecting the processing. Centered on the value of our services, we are able to complete projects efficiently with fewer errors. The process reduces our expenses and lowers the cost of metal fabrication.

Depending on your requirement, we provide you with the following surface finishing for your sheet metal parts. We have manual department to responsible for it and work great and reliably with our suppliers for more finishing services.

Aluminum (all alloys)、Cold-rolled steel、Hot rolled steel、Stainless steel (300&400 Series)、Galvanized steel、Iron、Brass、Bronze、Copper

Please feel free to contact us if you have other material requests.

Sheet metal is thin and soft. It is harder to be machined than a metal block. The bending, laser cutting, and stamping technologies can provide the same ability to form ideal shapes or patterns faster and easier.

Commonly, we recommend sheet metal bending and laser cutting for small batch production and stamping for large-scale production.

For the meal sheet parts like bracket, chassis, sheet metal fabrication requires lower investment in tooling and preparation cost. Sheet metal has a definite advantage at delivery and transport as its low weight and thin gauge.

Medical、Automotive、Electronics、Office furniture、General industries、Defense